MIMAC: 3D Printed Housing

2023-2024

Proposal

Our proposal, Mare Island Maker Community (MIMAC), is situated in Vallejo, California, and draws inspiration from the historical significance of the site. Established as the first U.S. naval shipyard on the Pacific Coast in 1854, Mare Island played a central role during the World Wars as the major hub for shipbuilding, repair, and maintenance.

Our goal is to preserve the historic character of the former naval shipyard by revitalizing it through residential and mixed-use developments, which incorporate modern amenities and sustainable design principles that can enhance the quality of life for new residents and attract new businesses.

To kickstart this transformation, we propose an inaugural lighthouse project that embraces the site’s ‘manufacturing culture’ and envisions a small residential community tailored for makers, artists, and innovators.

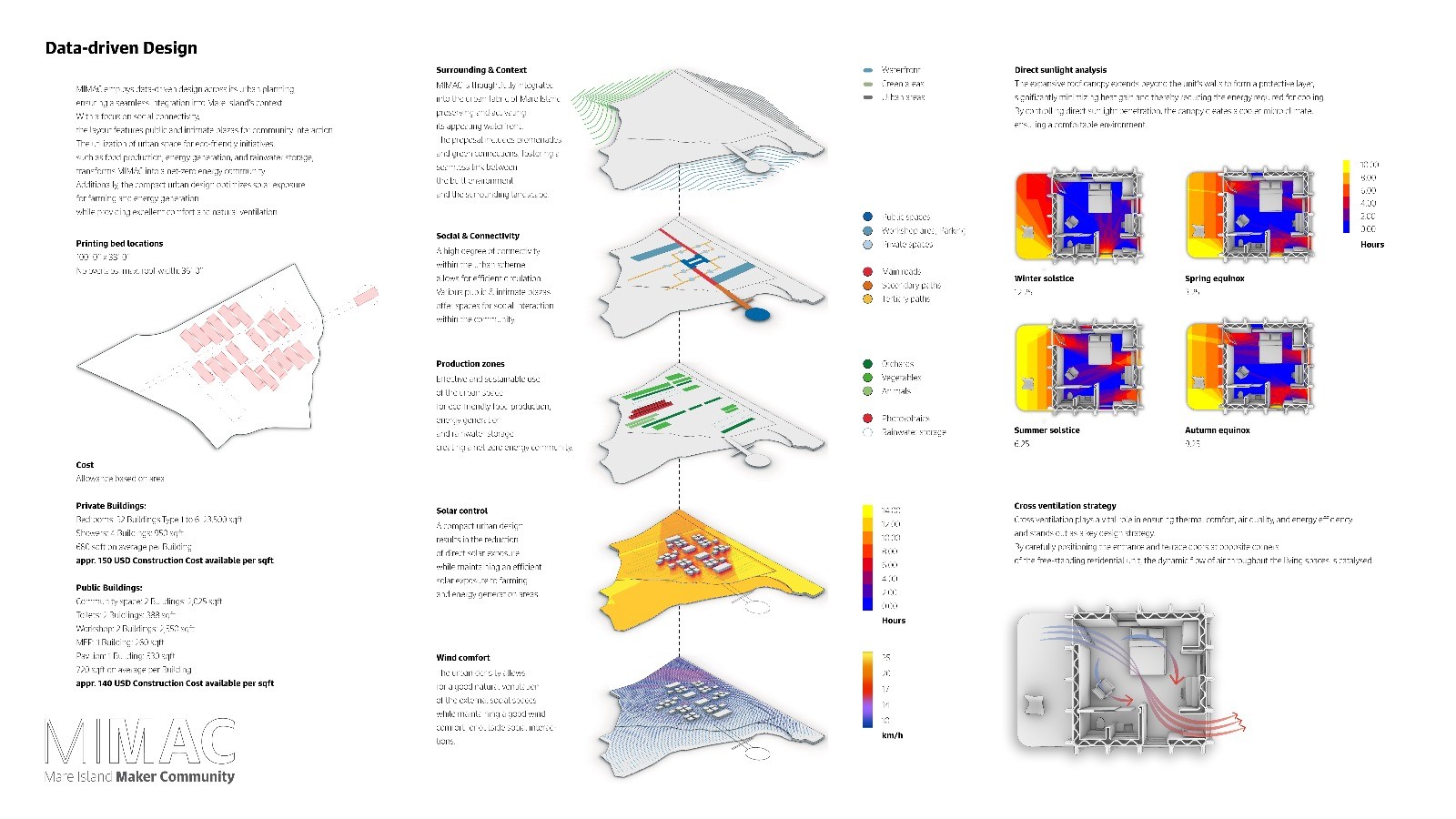

Data-driven Design

MIMAC employs data-driven design across its urban planning, ensuring a seamless integration into Mare Island’s context. With a focus on social connectivity, the layout features public and intimate plazas for community interaction.

The utilization of urban space for eco-friendly initiatives, such as food production, energy generation, and rainwater storage, transforms MIMAC into a net-zero energy community. Additionally, the compact urban design optimizes solar exposure for farming and energy generation while providing excellent comfort and natural ventilation of spaces for social interactions.

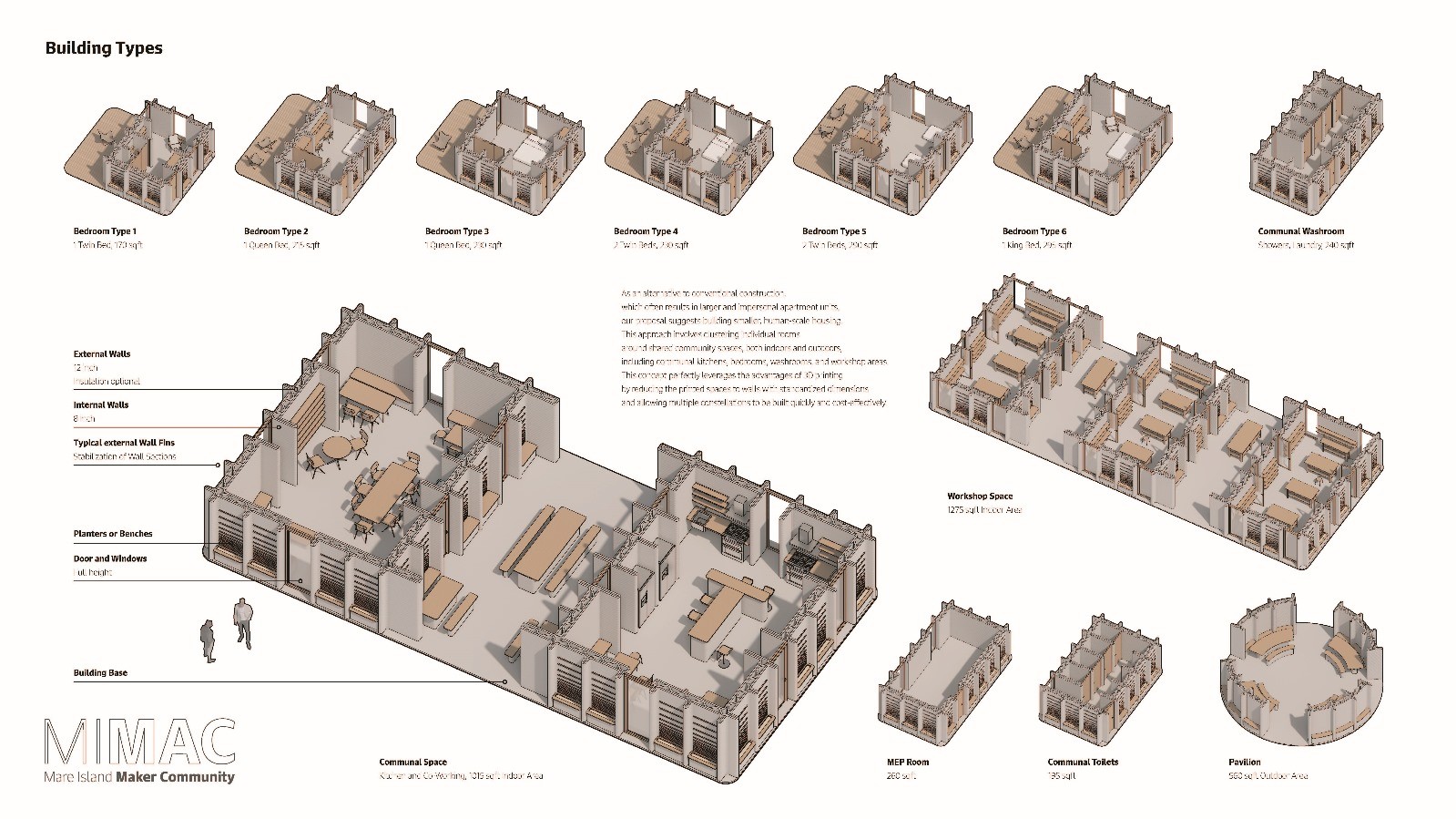

Building Types

As an alternative to conventional construction, which often results in larger and impersonal apartment units, our proposal suggests building smaller, human-scale housing. This approach involves clustering individual rooms around shared community spaces, both indoors and outdoors, including communal kitchens, bedrooms, washrooms, and workshop areas.

This concept perfectly leverages the advantages of 3D printing by reducing the printed spaces to walls with standardized dimensions and allowing multiple constellations to be built quickly and cost-effectively.

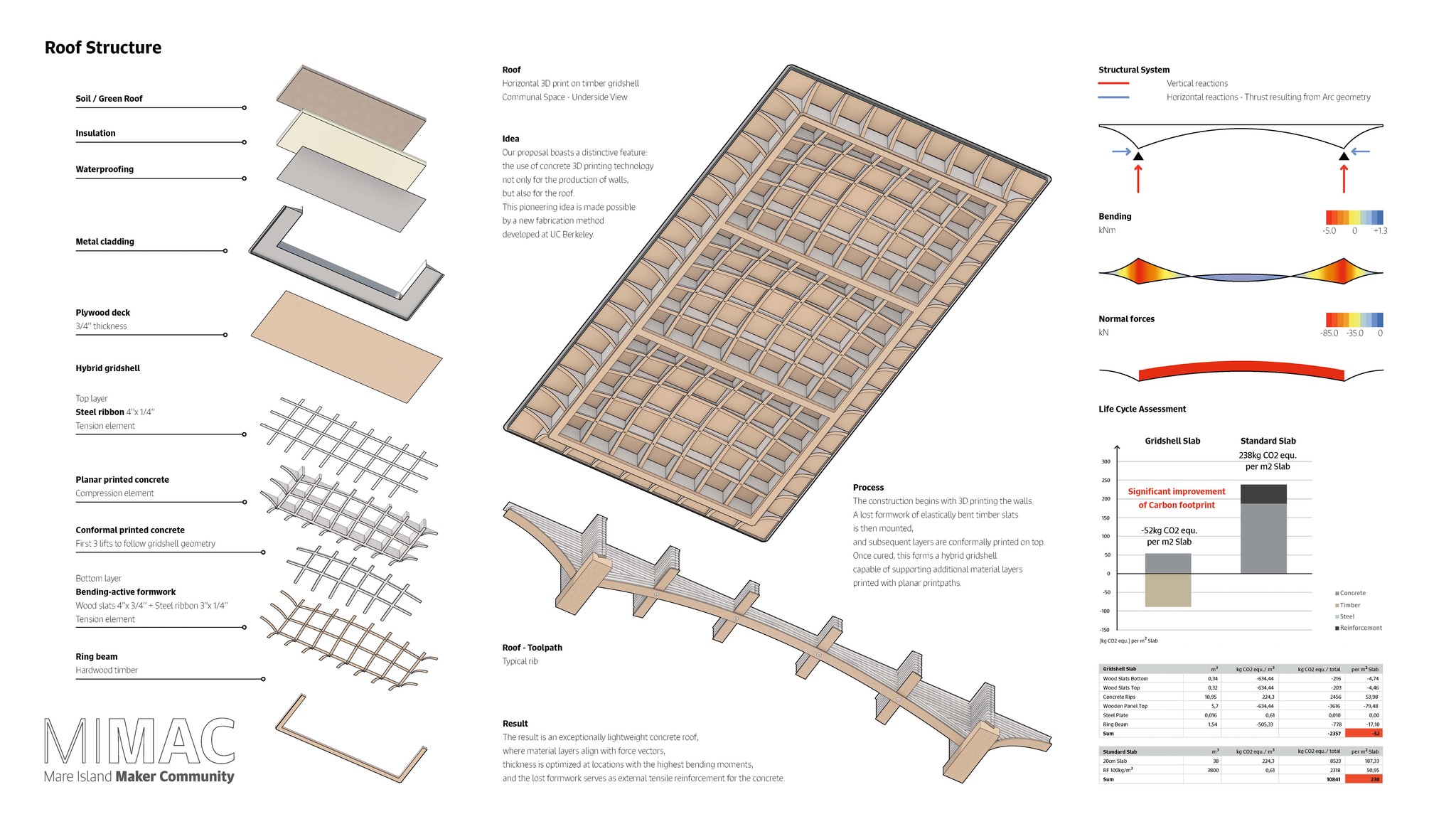

Roof Structure

Our proposal boasts a distinctive feature: the use of concrete 3D printing technology not only for the production of walls, but also for the roof. This pioneering idea is made possible by a new fabrication method developed at UC Berkeley.

Here, the construction begins with 3D printing the walls. A lost formwork of elastically bent timber slats is then mounted, and subsequent layers are conformally printed on top. Once cured, this forms a hybrid grid shell capable of supporting additional material layers printed with planar print-paths.

The result is an exceptionally lightweight concrete roof, where material layers align with force vectors, thickness is optimized at locations with the highest bending moments, and the lost formwork serves as external tensile reinforcement for the concrete.

Stefanie Hickl, AlSager Wertel Architects (Germany)

Kai Wertel, AlSager Wertel Architects (Kuwait)

Yana Rudasevschi, AlSager Wertel Architects (Germany)

Prof. Simon Schleicher, UC Berkeley (USA)

Barrak Darweesh, UC Berkeley (USA)

Niklas Mühlich, Mühlich + Partner Architekten (Germany)

Piotr Kuschinsky, Differential (Poland)

Zhongming Fang, Differential (USA)

Philipp Längst, str.ucture (Germany)